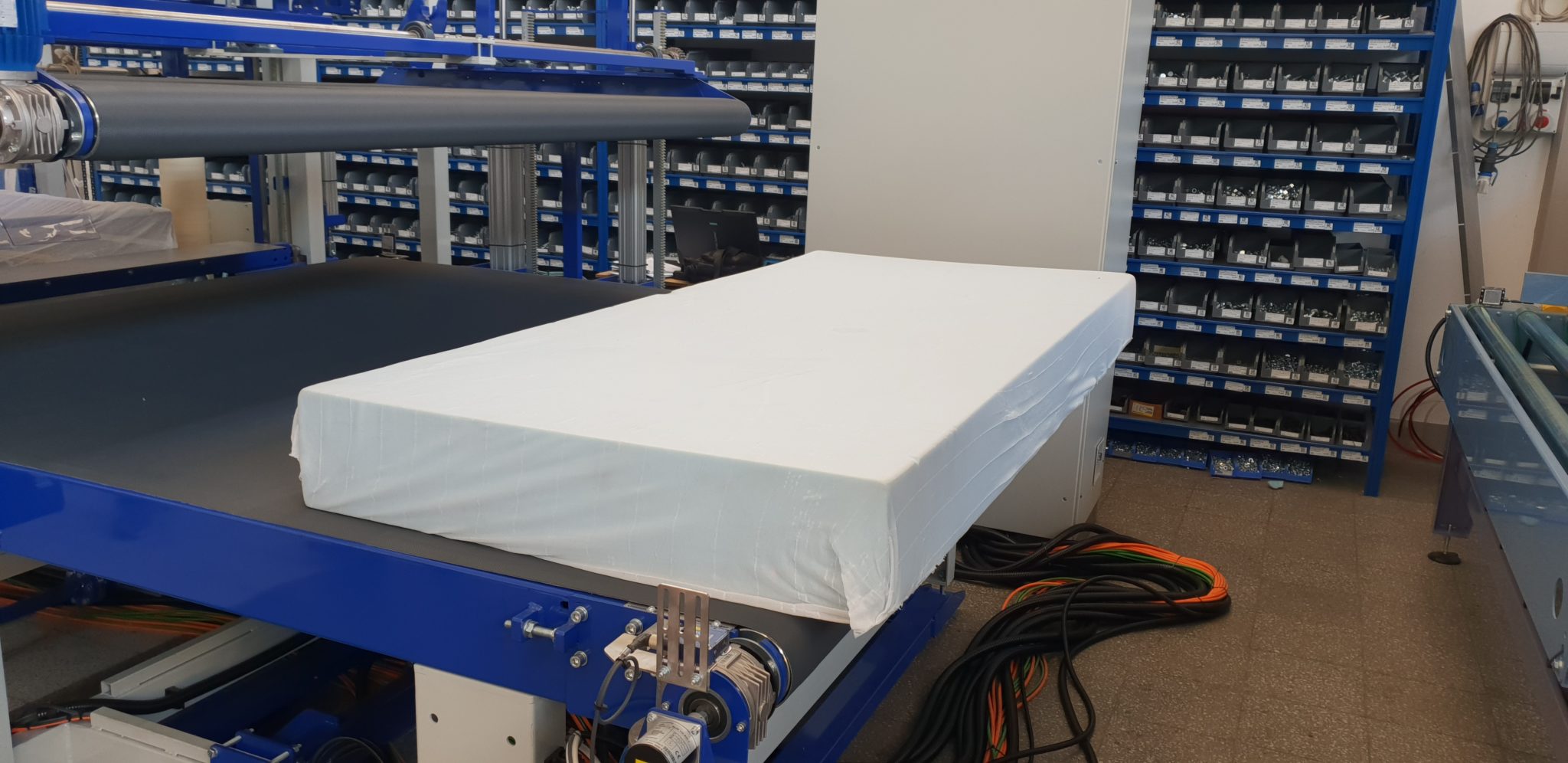

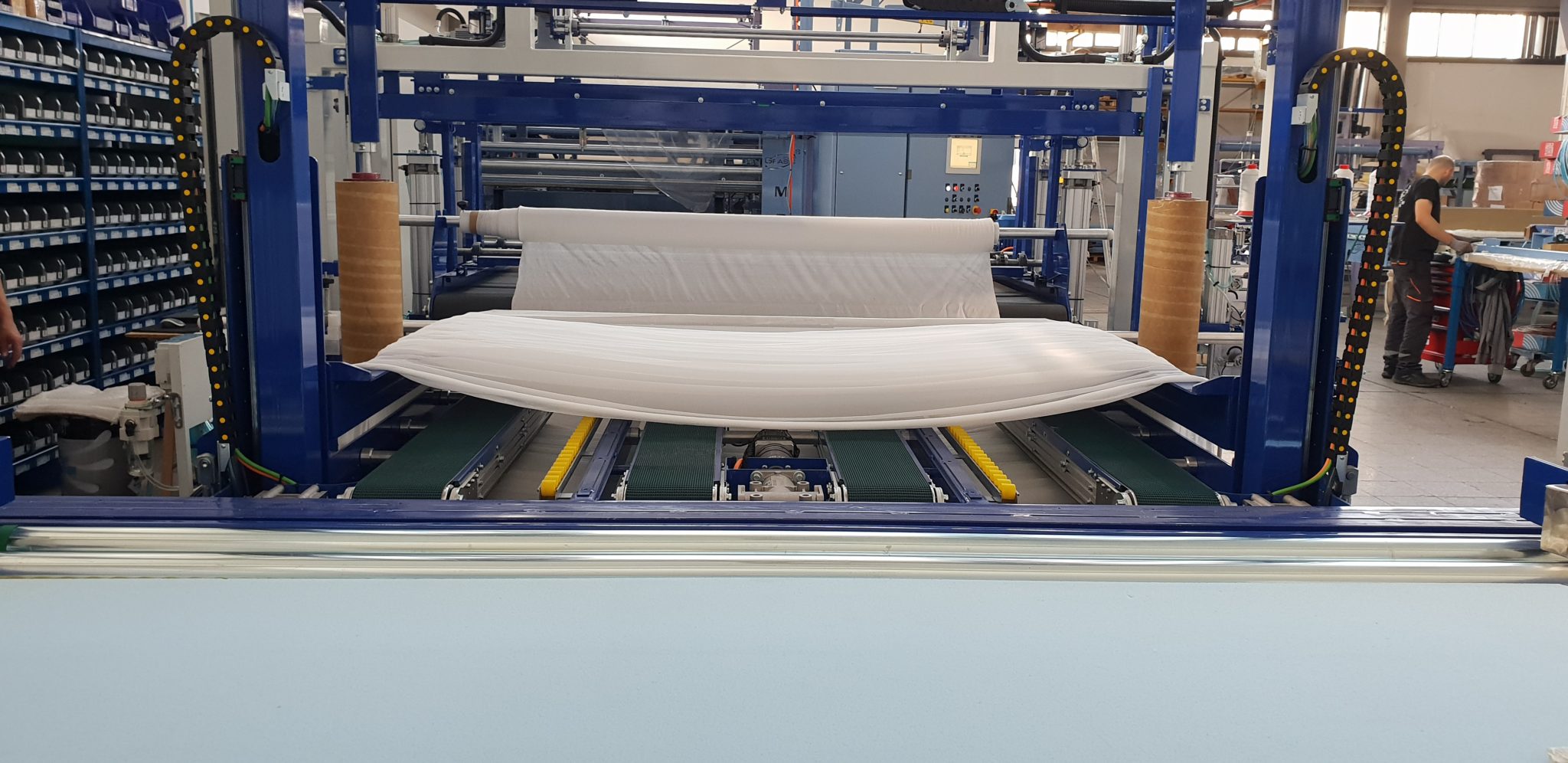

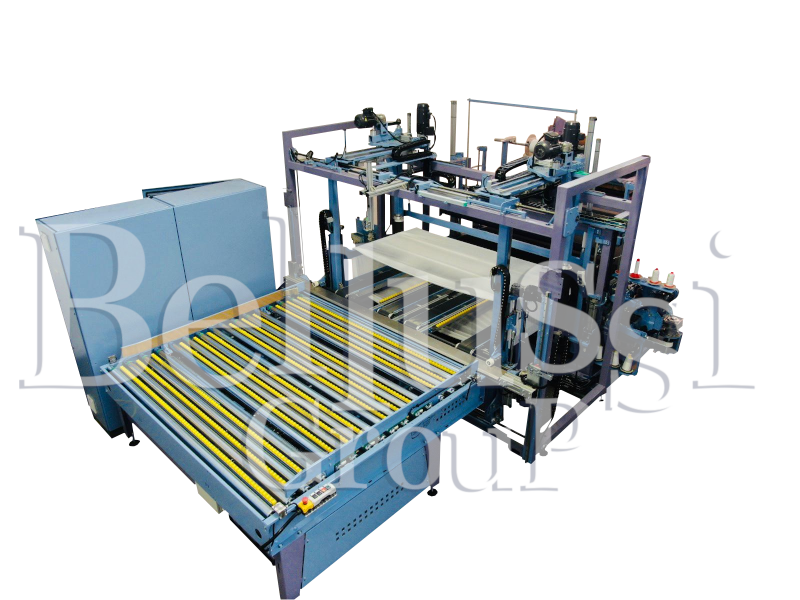

“TRICOT LINE” is an innovative automatic tricot/yersa filling machine, ideal for inserting foam sheets into tubes. This special design is equipped with motor-driven conveyor belts and steel rods to exert even pressure on the foam surface, completely eliminating friction during material insertion.

The machine is equipped with a motor-driven roller conveyor with an automatic centering drive, which facilitates the insertion of plates with large dimensions and considerable weight. It is a fully autonomous machine that is ideal for large-scale production and can operate continuously 24 godin a day.

Thanks to its reliability and robustness, the “TRICOT LINE” machine is ideal for incorporation into a production line with other machines. It is not only an efficient, but also a cost-effective machine that speeds up the production process, ensuring excellent quality of the final product. The machine is an ideal tool for automating and improving the production process of tricot and jersey fabrics.

| VOLTAGE | |||

| 400 V+N+T, 50/60 Hz | |||

| NOMINAL POWER | |||

| 9 kW | |||

| AIR PRESSURE | |||

| 6-8 BAR | |||

| MAXIMUM HEIGHT | |||

| 5-50 cm | |||

| WEIGHT | |||

| 3250 kg | |||

| EFFICIENCY | |||

| 2 cycles/ minute | |||

| DIMENSIONS(mm) | LENGTH | WIDTH | HEIGHT |

| TRICOT LINE (mm) | 5500 | 3500 | 2200 |

| WORKING SURFACE | LENGTH | WIDTH | |

| TRICOT LINE(mm) | 70 | 220 |

TRICOT AND JERSEY FILLING MACHINE “TRICOT LINE”

“TRICOT LINE” is an innovative automatic tricot/yersa filling machine, ideal for inserting foam sheets into tubes. This special design is equipped with motor-driven conveyor belts and steel rods to exert even pressure on the foam surface, completely eliminating friction during material insertion.

The machine is equipped with a motor-driven roller conveyor with an automatic centering drive, which facilitates the insertion of plates with large dimensions and considerable weight. It is a fully autonomous machine that is ideal for large-scale production and can operate continuously 24 godin a day.

Thanks to its reliability and robustness, the “TRICOT LINE” machine is ideal for incorporation into a production line with other machines. It is not only an efficient, but also a cost-effective machine that speeds up the production process, ensuring excellent quality of the final product. The machine is an ideal tool for automating and improving the production process of tricot and jersey fabrics.

| VOLTAGE | |||

| 400 V+N+T, 50/60 Hz | |||

| NOMINAL POWER | |||

| 9 kW | |||

| AIR PRESSURE | |||

| 6-8 BAR | |||

| MAXIMUM HEIGHT | |||

| 5-50 cm | |||

| WEIGHT | |||

| 3250 kg | |||

| EFFICIENCY | |||

| 2 cycles/ minute | |||

| DIMENSIONS(mm) | LENGTH | WIDTH | HEIGHT |

| TRICOT LINE (mm) | 5500 | 3500 | 2200 |

| WORKING SURFACE | LENGTH | WIDTH | |

| TRICOT LINE(mm) | 70 | 220 |

Ask about:

Ask about: Zadaj pytanie

Zadaj pytanie Drukuj / Print

Drukuj / Print