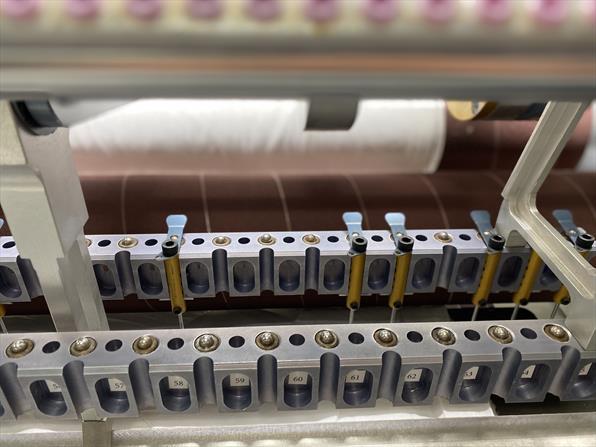

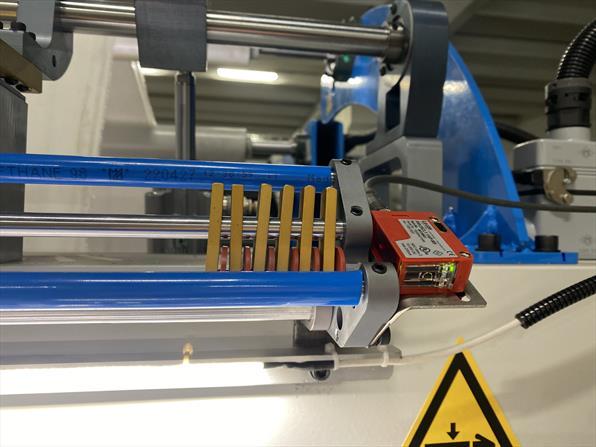

Automatic multi-needle quilting machine of lock-stitch due to a particular interlacement of the stitch guarantees a perfect stability of stitching in time and a high precision of designs.

Thanks to its easy regulation by a user friendly and intuitive digital control with touch screen monitor the machine is simple to use and is suitable for a continuous change of needles in search of new designs and for small series production.

Robust structure and all mechanical parts made with a maximum care and precision provide an operational durability and a possibility of usage for 24 hours a day.

All moving components are set in motion by lubricated ball bearings guaranteeing the precision in time. Carriage and rolls motion is completely monitored by a digital control that according to the position of the needle commands the movement in speed and acceleration optimal for execution of perfect stitching and designs even on delicate fabrics.

| DPAT 66″ | DPAT 110″ | |

| Max quilting speed | 650 OBR/MIN | 650 OBR/MIN |

| Carriage cross motion | 304,8 MM=12 INCHES | 304,8 MM=12 INCHES |

| Number of needle bars | 2 bars at 3 inch distance | 2 bars at 3 inch distance |

| Number of needles | 66 at 1 inch distance | 110 at 1 inch distance |

| Max material width | 2050 MM | 3170 MM |

| Max quilting width | 1650-1955 MM | 2770=3070 MM |

| Approximate weight | 3500 KG | 4800 KG |

| Type of quilting | 360° | 360° |

| Feeding | 400V 3 phases + ground + midpoint | 400V 3 phases + ground + midpoint |

| Current | 15 KW | 15 KW |

| Air pressure | 8 BAR | 8 BAR |

SHUTTLE STITCH QUILTING MACHINE DPAT 66/110

Automatic multi-needle quilting machine of lock-stitch due to a particular interlacement of the stitch guarantees a perfect stability of stitching in time and a high precision of designs.

Thanks to its easy regulation by a user friendly and intuitive digital control with touch screen monitor the machine is simple to use and is suitable for a continuous change of needles in search of new designs and for small series production.

Robust structure and all mechanical parts made with a maximum care and precision provide an operational durability and a possibility of usage for 24 hours a day.

All moving components are set in motion by lubricated ball bearings guaranteeing the precision in time. Carriage and rolls motion is completely monitored by a digital control that according to the position of the needle commands the movement in speed and acceleration optimal for execution of perfect stitching and designs even on delicate fabrics.

| DPAT 66″ | DPAT 110″ | |

| Max quilting speed | 650 OBR/MIN | 650 OBR/MIN |

| Carriage cross motion | 304,8 MM=12 INCHES | 304,8 MM=12 INCHES |

| Number of needle bars | 2 bars at 3 inch distance | 2 bars at 3 inch distance |

| Number of needles | 66 at 1 inch distance | 110 at 1 inch distance |

| Max material width | 2050 MM | 3170 MM |

| Max quilting width | 1650-1955 MM | 2770=3070 MM |

| Approximate weight | 3500 KG | 4800 KG |

| Type of quilting | 360° | 360° |

| Feeding | 400V 3 phases + ground + midpoint | 400V 3 phases + ground + midpoint |

| Current | 15 KW | 15 KW |

| Air pressure | 8 BAR | 8 BAR |

Ask about:

Ask about:

More information

More information Drukuj / Print

Drukuj / Print