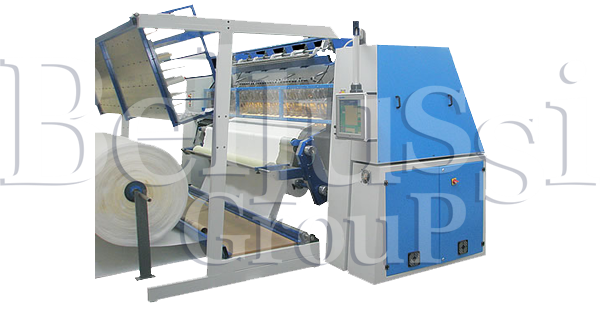

Double chain stitch technology permits to achieve a high speed of quilting and productivity that make of the quilter an indispensable element for big productions even for 24 hours a day.

Continuous research and experiments have brought to the construction of a simple, robust and reliable computerized multi needle quilter.

Double chain stitch technology permits to achieve a high speed of quilting and productivity that make of the quilter an indispensable element for big productions even for 24 hours a day..

Robust structure provides an operational durability; an ideal balance of all mechanical parts drawn out of a full piece makes the motion of the machine gentle and silent.

Moving components are set in motion by lubricated ball bearings guaranteeing the precision in time.

Thoroughly studied and developed electronics is presented by a simple, intuitive and operator’s friendly digital control with Touch Screen constantly updated following clients’ needs and advises.

| DPAF90″ | DPAF120″ | |

| Max speed | 1200 stitches/min | 1200 stitches/min |

| Carriage cross motion | 304,8 mm= 12 inches | 304,8 mm= 12 inches |

| Number of needle bars | 3 bars at 3 inches distance | 3 bars at 3 inches distance |

| Number of needles | 90 at 1 inch distance | 120 at 1 inch distance |

| Filomatic | 40 needles, 40 crochet | 60 needles, 60 crochet |

| Max material width | 2660 MM | 3422 MM |

| Max quilting width | 2260 – 2560 MM | 3022 – 3326 MM |

| Approximate weight | 6000 KG | 7000 KG |

| Type of quilting | 360° | 360° |

| Feeding | 400 V 3 PHASES+NEUTRAL+UZIOM | 400 V 3 PHASES+NEUTRAL+UZIOM |

| Current | 15 KW | 15 KW |

| Air pressure | 8 BAR | 8 BAR |

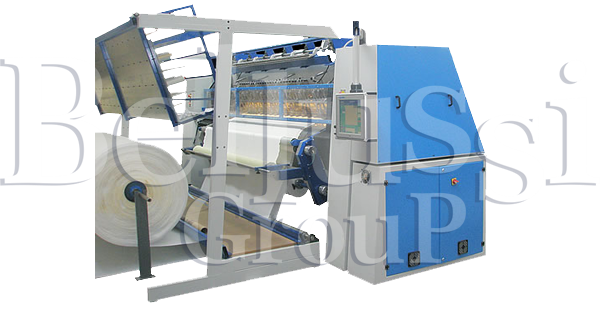

QUILTING MACHINE WITH CHAIN STITCH DPAF 90/120

Continuous research and experiments have brought to the construction of a simple, robust and reliable computerized multi needle quilter.

Double chain stitch technology permits to achieve a high speed of quilting and productivity that make of the quilter an indispensable element for big productions even for 24 hours a day..

Robust structure provides an operational durability; an ideal balance of all mechanical parts drawn out of a full piece makes the motion of the machine gentle and silent.

Moving components are set in motion by lubricated ball bearings guaranteeing the precision in time.

Thoroughly studied and developed electronics is presented by a simple, intuitive and operator’s friendly digital control with Touch Screen constantly updated following clients’ needs and advises.

| DPAF90″ | DPAF120″ | |

| Max speed | 1200 stitches/min | 1200 stitches/min |

| Carriage cross motion | 304,8 mm= 12 inches | 304,8 mm= 12 inches |

| Number of needle bars | 3 bars at 3 inches distance | 3 bars at 3 inches distance |

| Number of needles | 90 at 1 inch distance | 120 at 1 inch distance |

| Filomatic | 40 needles, 40 crochet | 60 needles, 60 crochet |

| Max material width | 2660 MM | 3422 MM |

| Max quilting width | 2260 – 2560 MM | 3022 – 3326 MM |

| Approximate weight | 6000 KG | 7000 KG |

| Type of quilting | 360° | 360° |

| Feeding | 400 V 3 PHASES+NEUTRAL+UZIOM | 400 V 3 PHASES+NEUTRAL+UZIOM |

| Current | 15 KW | 15 KW |

| Air pressure | 8 BAR | 8 BAR |

Ask about:

Ask about:

More information

More information Drukuj / Print

Drukuj / Print