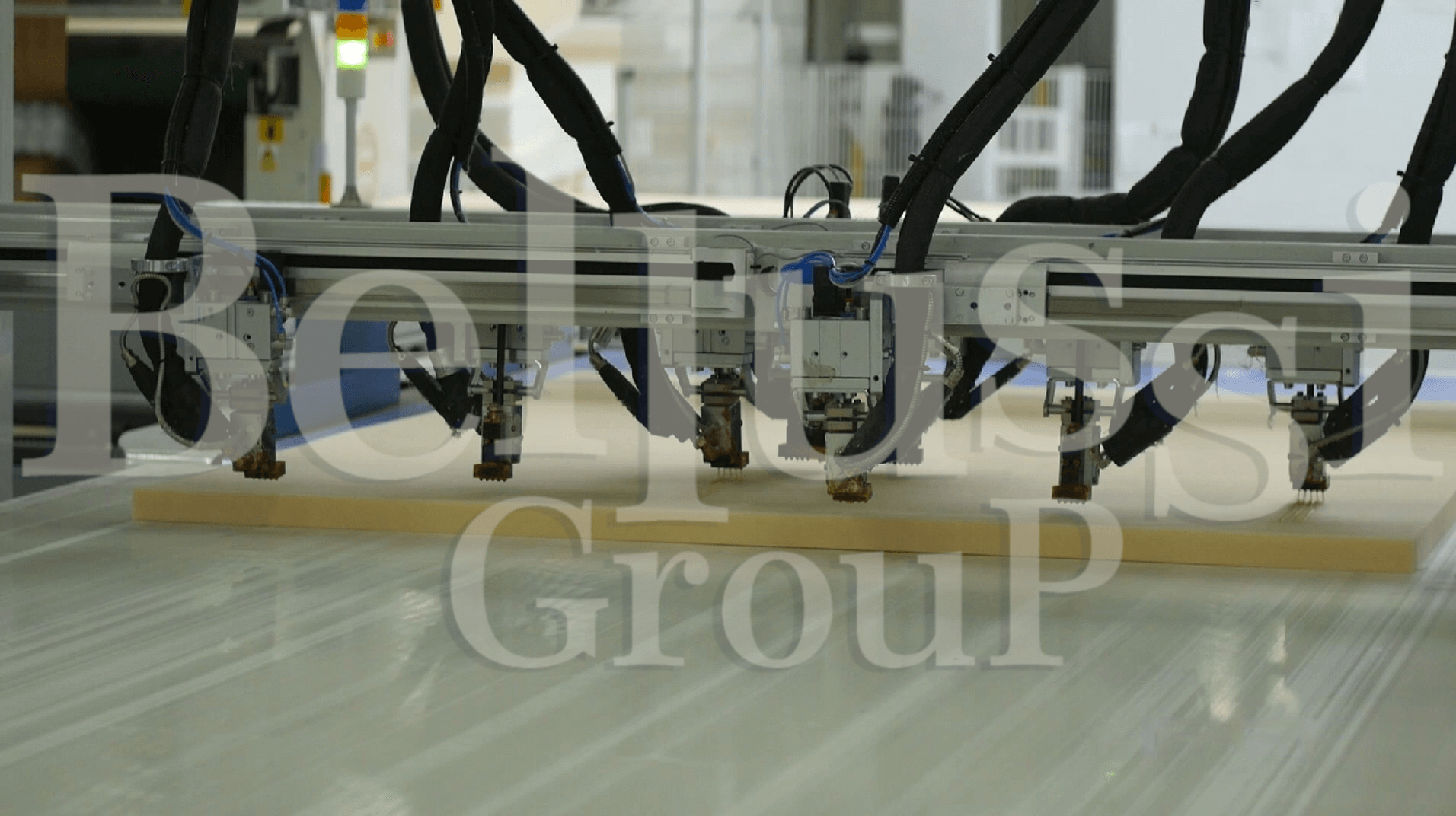

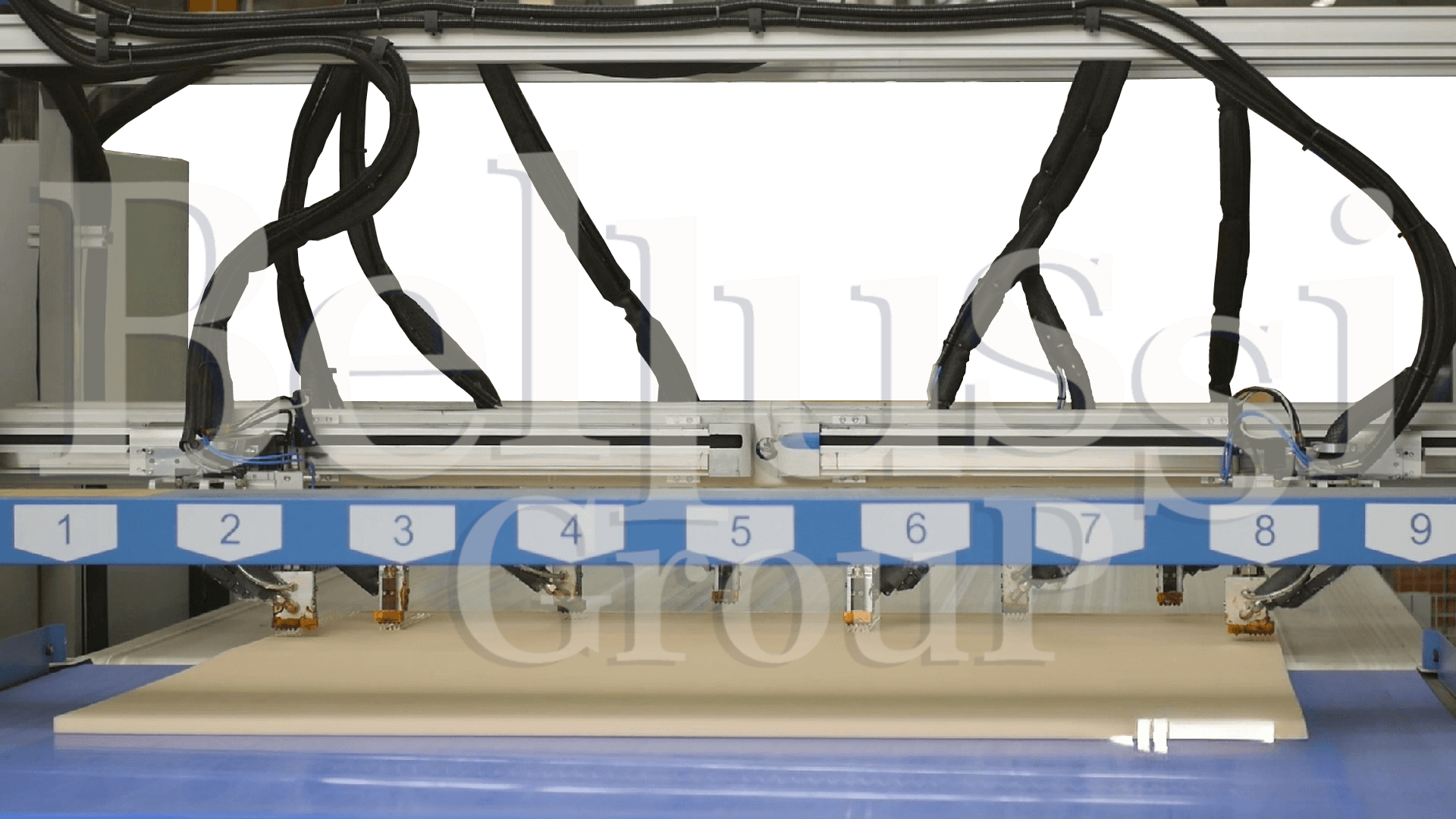

The AX-H hotmelt machine has been specially designed for maximum automation in the glue application process in mattress manufacturing. It makes it possible to apply hotmelt glue in a precise manner on any type of product. The AX-H machine can operate independently as a stand-alone station, or in line with an assembly station and press. The AX-H station is fully automated and has the ability to autonomously manage the glue feeding phases by controlling the timing and nozzle paths.

The paths for the hotmelt glue feeding nozzles can be entered into the program as recipes or, thanks to sensors, adapt themselves to the dimensions of the part to be glued. The AX-H machine is numerically controlled via a built-in computer, and consists of a loading conveyor belt, a non-stick coated conveyor belt, above which is a spray bar. It is possible to equip the beam with at least 5 spray nozzles, which apply the adhesive (multi-line, single-line or spiral) around the perimeter or in the middle of the foam according to customer specifications. Depending on the type of glue used and production requirements, the AX-H hot glue machine will be equipped with the best glue feeding system (melter, nozzles, pump, etc.)

| VOLTAGE | |||

| 400/480 V, 3ph, 50/60 Hz | |||

| AMPERAGE | |||

| 13 A | |||

| AIR CONSUMPTION | |||

| 19 NL/min | |||

| AIR PRESSURE | |||

| 6 BAR | |||

| MOTOR TYPE | |||

| 1 AC | |||

| WEIGHT | |||

| 600 kg | |||

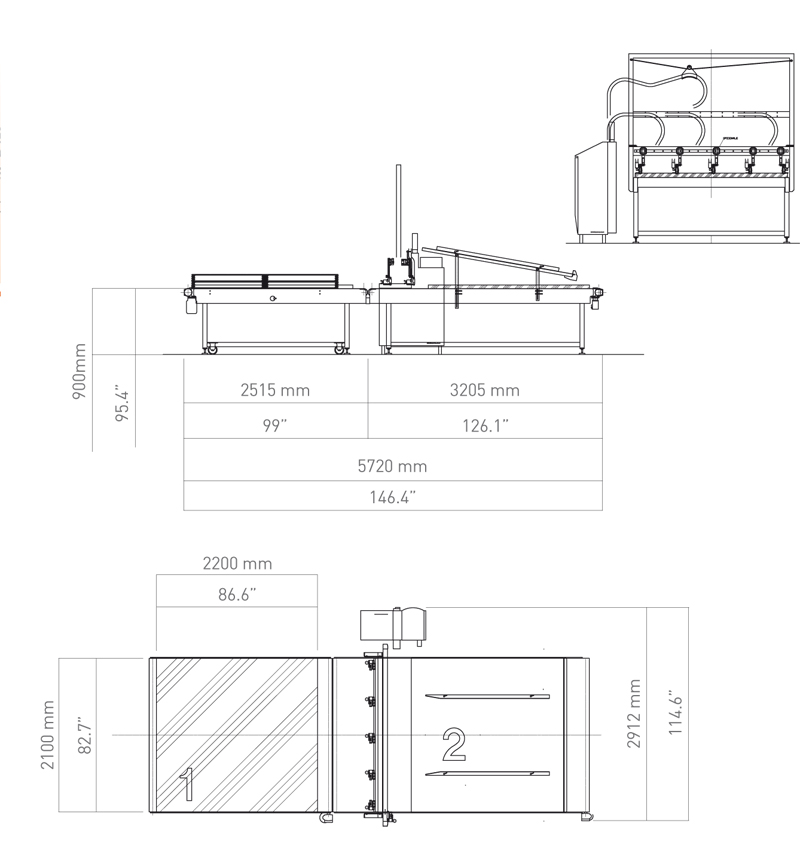

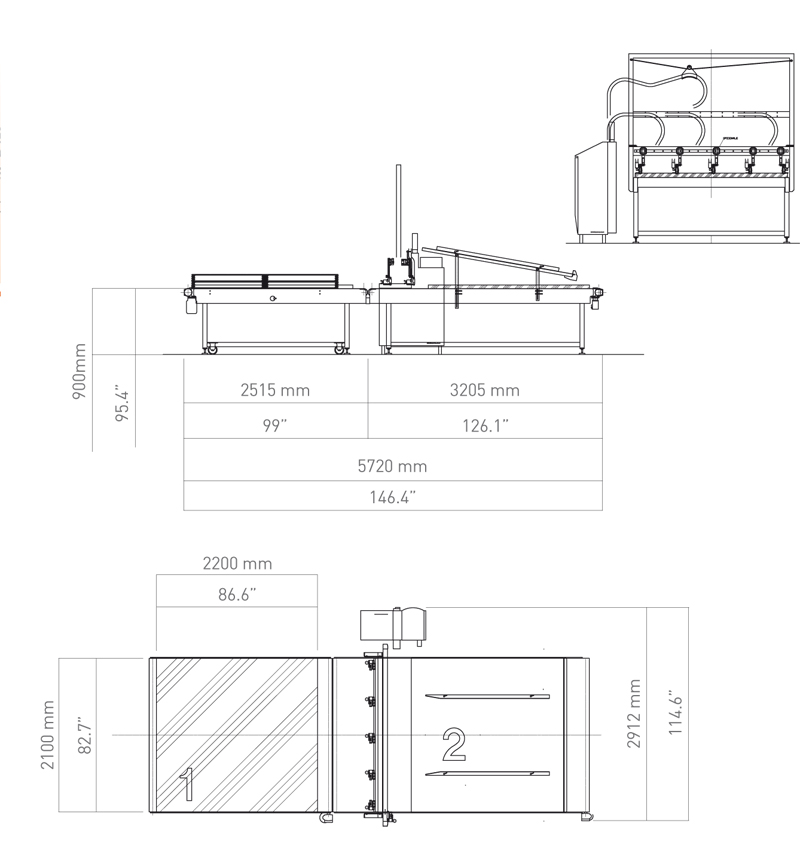

| DIMENSIONS | LENGTH | WIDTH | HEIGHT |

| AX-H (mm) | 5720 | 2912 | 2000 |

| WORKING SURFACE | LENGTH | WIDTH | HEIGHT |

| AX-H (mm) | 2200 | 2100 | 400 |

AUTOMATIC ROLLER GLUING MACHINE AX-H

The AX-H hotmelt machine has been specially designed for maximum automation in the glue application process in mattress manufacturing. It makes it possible to apply hotmelt glue in a precise manner on any type of product. The AX-H machine can work independently as a stand-alone station, or in line with an assembly station and press. The AX-H station is fully automated and has the ability to autonomously manage the glue application phases by controlling the timing and nozzle paths. The paths for the nozzles feeding the hot melt glue can be entered into the program as recipes or, thanks to sensors, adapt themselves to the dimensions of the part to be glued. The AX-H machine is numerically controlled via a built-in computer, and consists of a loading conveyor belt, a non-stick coated conveyor belt, above which is a spray bar. It is possible to equip the beam with at least 5 spray nozzles, which apply glue (multi-line, single-line or spiral) around the perimeter or in the middle of the foam according to customer specifications. Depending on the type of adhesive used and production requirements, the AX-H hot glue machine will be equipped with the best adhesive feeding system (melter, nozzles, pump, etc.).

The AX-H hotmelt machine has been specially designed for maximum automation in the glue application process in mattress manufacturing. It makes it possible to apply hotmelt glue in a precise manner on any type of product. The AX-H machine can work independently as a stand-alone station, or in line with an assembly station and press. The AX-H station is fully automated and has the ability to autonomously manage the glue application phases by controlling the timing and nozzle paths. The paths for the nozzles feeding the hot melt glue can be entered into the program as recipes or, thanks to sensors, adapt themselves to the dimensions of the part to be glued. The AX-H machine is numerically controlled via a built-in computer, and consists of a loading conveyor belt, a non-stick coated conveyor belt, above which is a spray bar. It is possible to equip the beam with at least 5 spray nozzles, which apply glue (multi-line, single-line or spiral) around the perimeter or in the middle of the foam according to customer specifications. Depending on the type of adhesive used and production requirements, the AX-H hot glue machine will be equipped with the best adhesive feeding system (melter, nozzles, pump, etc.).

| VOLTAGE | |||

| 400/480 V, 3ph, 50/60 Hz | |||

| AMPERAGE | |||

| 13 A | |||

| AIR CONSUMPTION | |||

| 19 NL/min | |||

| AIR PRESSURE | |||

| 6 BAR | |||

| MOTOR TYPE | |||

| 1 AC | |||

| WEIGHT | |||

| 600 kg | |||

| DIMENSIONS | LENGTH | WIDTH | HEIGHT |

| AX-H (mm) | 5720 | 2912 | 2000 |

| WORKING SURFACE | LENGTH | WIDTH | HEIGHT |

| AX-H (mm) | 2200 | 2100 | 400 |

Ask about:

Ask about: Zadaj pytanie

Zadaj pytanie Drukuj / Print

Drukuj / Print