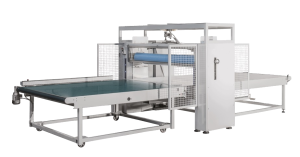

AX-RS roller gluing machine is an ideal solution for mattress and upholstery manufacturers and other productions where the lamination process is used. The AX-RS rolling machine has been designed for use with single-component water-based glues. It can perform several types of gluing, for example:

– Gluing on tips only

– Gluing on flat surfaces

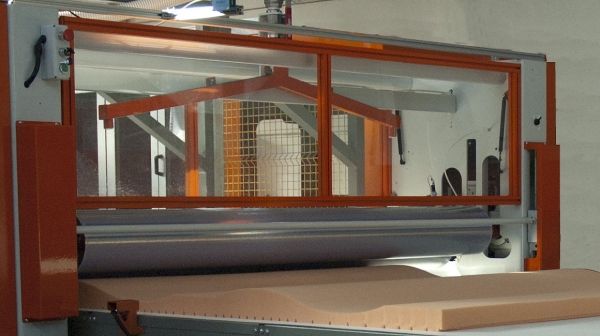

The AX-RS machine consists of 2 rollers one for application and one for batching through which the glue is applied and the adhesive quantity distributed is adjusted.

The robust and precise mechanics of the AX-RS gluing machine and the accuracy with which the dosing and spreading rollers are manufactured ensure very important advantages among which are: the possibility of an extremely accurate adjustment and thanks to this, manufacturers consequently reduce the amount of applied glue and the possibility to work at high speed under all conditions and with any type of material, also of different thickness whether it is smooth or embossed.

The adjustment of the quantity of glue to be applied may be executed by operating on the manual micrometric handwheel.

This machine consists of: loading conveyor belt with wheels to facilitate cleaning operations, processing belt in stick-proof material, glue bridge which contains the rollers group, and it is managed by a PLC touch screen.

The AX-RS glue applicator is able to work as a stand-alone station or in line with other machines and it is also the ideal solution for manufacturers of couches, sofas, armchairs and multilayer or box mattresses, thanks to the possibility of simultaneous higher productivity, great flexibility and a significant reduction of productions costs.

| ELECTRICAL SUPPLY | |||

| 400/480 V, 3ph, 50/60 Hz | |||

| AMPERAGE | |||

| 11 A | |||

| WEIGHT | |||

| 1800 kg | |||

| MOTOR TYPE | |||

| 1AC & 1 BRUSHLESS | |||

| AIR PRESSURE | |||

| DIMENSIONS | LENGHT | WIDTH | HEIGHT |

| AX-RS (mm) | 6025 | 3310 | 1865 |

| WORKING SURFACE | LENGHT | WIDTH | HEIGHT |

| AX-RS (mm) | 2200 | 2100 | 300/ 395 |

AUTOMATIC ROLLER GLUING MACHINE AX-RS

AX-RS roller gluing machine is an ideal solution for mattress and upholstery manufacturers and other productions where the lamination process is used. The AX-RS rolling machine has been designed for use with single-component water-based glues. It can perform several types of gluing, for example:

– Gluing on tips only

– Gluing on flat surfaces

The AX-RS machine consists of 2 rollers one for application and one for batching through which the glue is applied and the adhesive quantity distributed is adjusted.

The robust and precise mechanics of the AX-RS gluing machine and the accuracy with which the dosing and spreading rollers are manufactured ensure very important advantages among which are: the possibility of an extremely accurate adjustment and thanks to this, manufacturers consequently reduce the amount of applied glue and the possibility to work at high speed under all conditions and with any type of material, also of different thickness whether it is smooth or embossed.

The adjustment of the quantity of glue to be applied may be executed by operating on the manual micrometric handwheel.

This machine consists of: loading conveyor belt with wheels to facilitate cleaning operations, processing belt in stick-proof material, glue bridge which contains the rollers group, and it is managed by a PLC touch screen.

The AX-RS glue applicator is able to work as a stand-alone station or in line with other machines and it is also the ideal solution for manufacturers of couches, sofas, armchairs and multilayer or box mattresses, thanks to the possibility of simultaneous higher productivity, great flexibility and a significant reduction of productions costs.

| ELECTRICAL SUPPLY | |||

| 400/480 V, 3ph, 50/60 Hz | |||

| AMPERAGE | |||

| 11 A | |||

| WEIGHT | |||

| 1800 kg | |||

| MOTOR TYPE | |||

| 1AC & 1 BRUSHLESS | |||

| AIR PRESSURE | |||

| DIMENSIONS | LENGHT | WIDTH | HEIGHT |

| AX-RS (mm) | 6025 | 3310 | 1865 |

| WORKING SURFACE | LENGHT | WIDTH | HEIGHT |

| AX-RS (mm) | 2200 | 2100 | 300/ 395 |

Ask about:

Ask about:

More information

More information Drukuj / Print

Drukuj / Print