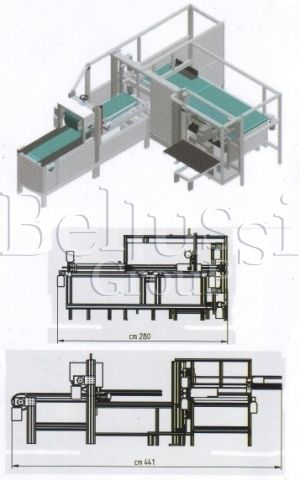

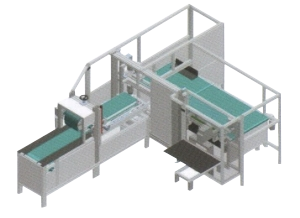

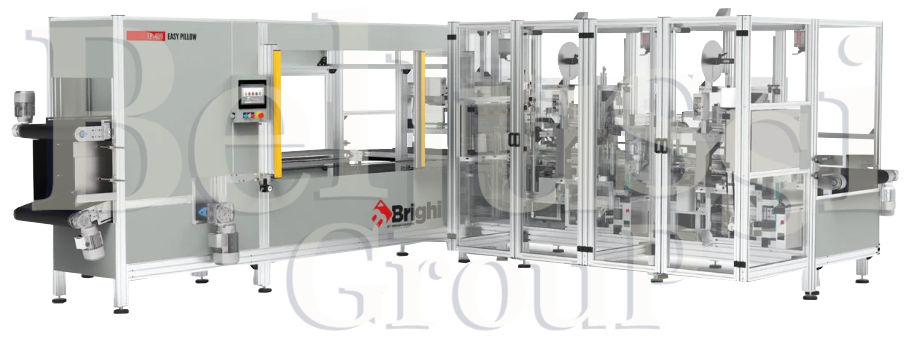

The CN400 line is a complete automatic line for the production of pillows and cushions for furniture, consisting of several units connected and synchronized with each other to ensure a high production standard and minimize the risk of human error.

The CN400 consists of an automatic insertion belt, a filling machine and an automatic sewing machine for the final sewing of the pillow cover.

The line has been programmed to produce pillows of various types and sizes. Fillings of rolled fiber, latex, thermo elastic foam, polyurethane foam and others can be used. It is also suitable for various types of pillowcases – cotton, nonwoven, stretch.

Production consists of the following steps: the operator places the pillowcase on the shoulders and the automatic cycle of insertion into the pillowcase, positioning of the pillow and final sewing with labeling begins.

On request: the support system of the filling material

Rolled fiber with foam, thermoelastic foam, visco latex, polyurethane foam, etc. are inserted into the machine through a special electronically powered belt.

On request (optional): the machine can be equipped with a special manual belt; one operator can then lay the insert and then the pillowcase without affecting productivity.

The CN400 line makes it possible to reduce labor costs, production space and the so-called dead time needed to remove the finished product from the belt. At the same time, it is able to guarantee high productivity combined with satisfactory quality of the final product without the need for special employee training.

It only takes one operator to position the pillowcase to start the automatic work cycle, so you can get as many as 6-7 filled pillows/minute, ready for sewing (the output depends on the size and type of materials).

| FURNITURE CUSHIONS | ||

| LENGTH | WIDTH | |

| STANDARD DIMENSIONS (cm) | min/max: 42/50 cm | min/max: 42/50 cm |

| BEDROOM PILLOWS | ||

| LENGTH | WIDTH | |

| STANDARD DIMENSIONS (cm) | min/max: 70/90 cm | min/max: 42/50 cm |

It is possible to design the machine for other sizes upon request.

The machine can be adjusted for different sizes and weights of inserts and pillowcases.

A special automatic device holds the pillowcase during the filling process and then transfers the pillow to the sewing phase. As soon as the pillowcase is inserted by the operator, the machine starts automatic alignment and tensioning to get the best quality product.

High-speed, electronic single-needle, three-thread, 5mm or two-needle, four-thread, 7mm overlocker with trimmer and work sensors.

The system is equipped with an automatic device to cut and bend the label from the roll and place it in the seam at the marked position, without affecting the output.

PILLOW PRODUCTION LINE CN 400

The CN400 line is a complete automatic line for the production of pillows and cushions for furniture, consisting of several units connected and synchronized with each other to ensure a high production standard and minimize the risk of human error.

The CN400 consists of an automatic insertion belt, a filling machine and an automatic sewing machine for the final sewing of the pillow cover.

The line has been programmed to produce pillows of various types and sizes. Fillings of rolled fiber, latex, thermoelastic foam, polyurethane foam and others can be used. It is also suitable for various types of pillowcases – cotton, nonwoven, stretch.

Production consists of the following steps: the operator places the pillowcase on the shoulders and the automatic cycle of insertion into the pillowcase, positioning of the pillow and final sewing with labeling begins.

On request: the support system of the filling material

Rolled fiber with foam, thermoelastic foam, visco latex, polyurethane foam, etc. are fed into the machine via a special electronically powered belt.

On request (optional): the machine can be equipped with a special manual belt; one operator can then lay the insert and then the pillowcase without affecting productivity.

The CN400 line makes it possible to reduce labor costs, production space and the so-called dead time needed to remove the finished product from the belt. At the same time, it is able to guarantee high productivity combined with satisfactory quality of the final product without the need for special employee training.

It only takes one operator to position the pillowcase to start the automatic work cycle, so you can get as many as 6-7 filled pillows/minute, ready for sewing (the output depends on the size and type of materials).

| FURNITURE CUSHIONS | ||

| LENGTH | WIDTH | |

| STANDARD DIMENSIONS (cm) | min/max: 42/50 cm | min/max: 42/50 cm |

| BEDROOM PILLOWS | ||

| LENGTH | WIDTH | |

| STANDARD DIMENSIONS (cm) | min/max: 70/90 cm | min/max: 42/50 cm |

It is possible to design the machine for other sizes upon request.

The machine can be adjusted for different sizes and weights of inserts and pillowcases.

A special automatic device holds the pillowcase during the filling process and then transfers the pillow to the sewing phase. As soon as the pillowcase is inserted by the operator, the machine starts automatic alignment and tensioning to get the best quality product.

High-speed, electronic single-needle, three-thread, 5mm or two-needle, four-thread, 7mm overlocker with trimmer and work sensors.

The system is equipped with an automatic device to cut and bend the label from the roll and place it in the seam at the marked position, without affecting the output.

Ask about:

Ask about:

More information

More information Drukuj / Print

Drukuj / Print