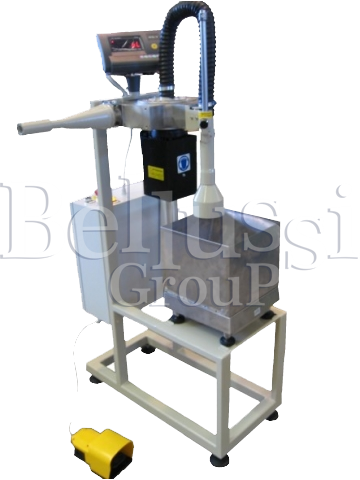

• This high-speed filling machine (8500rpm) is particularly suited for filling apparel with short fibres or down.

• The filling material is weighed manually in a 50-litre metal container fitted on load cells. The weighing accuracy is 0,2g and the emptying takes place by manually lowering a suction tube, which connects to the blower, down into the container.

• Once the desired weight is reached, the filling process is activated through a foot pedal, leaving the operator’s hands free to handle the item to be filled.

• The filling nozzle has diameter of just 40mm and is equipped with an air-discharge system, thus making it possible to fill very small pockets.

• Engine-braking takes place in approximately four tenths of a second and does not require any maintenance since it is achieved electronically.

• All parameters for acceleration, speed, deceleration and braking can be adjusted to suit individual requirements. Speed can be adjusted immediately through an inverter switch.

• The machine is built according to the requirements of the European Directives 2006/42/CE, 2004/108/CE, 2006/95/CE and subsequent amendments. The machine duly bears the CE marking.

| VOLTAGE | |||

| 380/480 V, 3ph, 50/60 Hz | |||

| NOMINAL POWER | |||

| 11,2 kW | |||

| WEIGHT | |||

| 780 kg | |||

| EFFICIENCY | |||

| 200 kg/ h | |||

| DIMENSIONS (mm) | LENGTH | WIDTH | HEIGHT |

| ANP4 (mm) | 2130 | 1000 | 1280 |

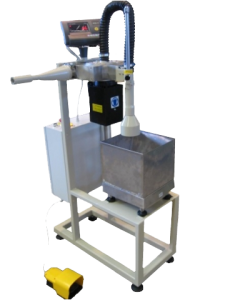

FILLING MACHINE ANP4

• This high-speed filling machine (8500rpm) is particularly suited for filling apparel with short fibres or down.

• The filling material is weighed manually in a 50-litre metal container fitted on load cells. The weighing accuracy is 0,2g and the emptying takes place by manually lowering a suction tube, which connects to the blower, down into the container.

• Once the desired weight is reached, the filling process is activated through a foot pedal, leaving the operator’s hands free to handle the item to be filled.

• The filling nozzle has diameter of just 40mm and is equipped with an air-discharge system, thus making it possible to fill very small pockets.

• Engine-braking takes place in approximately four tenths of a second and does not require any maintenance since it is achieved electronically.

• All parameters for acceleration, speed, deceleration and braking can be adjusted to suit individual requirements. Speed can be adjusted immediately through an inverter switch.

• The machine is built according to the requirements of the European Directives 2006/42/CE, 2004/108/CE, 2006/95/CE and subsequent amendments. The machine duly bears the CE marking.

| VOLTAGE | |||

| 380/480 V, 3ph, 50/60 Hz | |||

| NOMINAL POWER | |||

| 11,2 kW | |||

| WEIGHT | |||

| 780 kg | |||

| EFFICIENCY | |||

| 200 kg/ h | |||

| DIMENSIONS (mm) | LENGTH | WIDTH | HEIGHT |

| ANP4 (mm) | 2130 | 1000 | 1280 |

Ask about:

Ask about:

More information

More information Drukuj / Print

Drukuj / Print