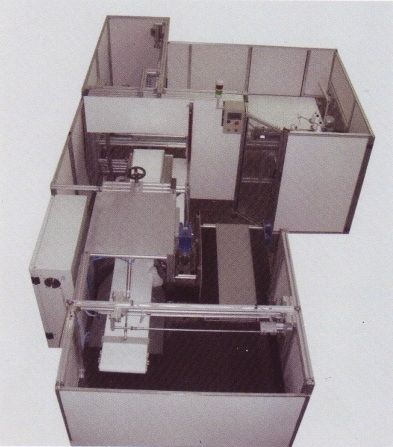

The unit CN400 is an automatic line for the production of pillows and cushions which important feature is the big productivity.

This system is composed of a stuffing machine complete with automatic feeding belt to convey the produce (rolled carded fibre, memory foam, visco latex and similar), of a system for positioning the pillowcase or cover, of an automatic sewing system with overlock machine (3 or 4 yarns) and of a labelling device (cut of label from the roll to be folded and included into the seam without affecting production time).

The Unit CN400 has a program suitable to different types and sizes of pillows and suitable to different kinds of fibre of different weights and to several products like visco latex, memory foam, polyurethane and similar. It is also suitable to different kinds of pillowcases and covers, in cotton, or nonwoven fabric or stretch fabric.

The unit CN400 is an automatic line for the production of pillows and cushions which important feature is the big productivity.

This system is composed of a stuffing machine complete with automatic feeding belt to convey the produce (rolled carded fibre, memory foam, visco latex and similar), of a system for positioning the pillowcase or cover, of an automatic sewing system with overlock machine (3 or 4 yarns) and of a labelling device (cut of label from the roll to be folded and included into the seam without affecting production time).

The Unit CN400 has a program suitable to different types and sizes of pillows and suitable to different kinds of fibre of different weights and to several products like visco latex, memory foam, polyurethane and similar. It is also suitable to different kinds of pillowcases and covers, in cotton, or nonwoven fabric or stretch fabric.

The production consists of the following phases: the operator inserts the cover and starts the automatic cycle for the feeding and the stuffing of the material, the pillows positioning to the sewing line and the pillow closing with label.

The unit CN400 is able to reduce the labour costs, the space into the production area, the dead time necessary to move the product. At the same time, it is able to guarantee a big output with a satisfactory quality of the finished product, without skilled personnel.

Only one operator is necessary to start the cycle, positioning the cover, being able to get 6 – 7 pillows or cushions / minute, stuffed and closed, ready to be packed.

Production depends on the size and type of products.

STANDARD SIZES FOR FURNISHING CUSHIONS:

Length min/max: 42/50 cm.

Width min/max: 42/50 cm.

STANDARD SIZES FOR PILLOWS:

Length min/max: 70/90 cm.

Width min/max: 42/50 cm.

We can arrange for other sizes on demand.

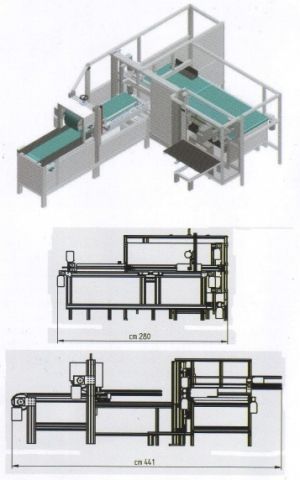

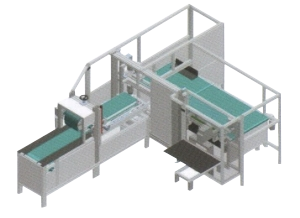

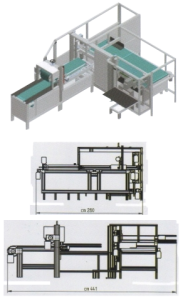

1. Stuffing system and automatic device for the cover.

2. Electronic stuffing machine with cover tensioning:

The machine can be adjusted to suit the different sizes and dimensions of the product to perform with the different kinds of cover.

A special automatic device is able to keep the cover during the automatic stuffing, transferring the pillow up to the sewing phase.

As soon as the cover is placed from the operator, the machine starts the automatic alignment, squaring and tension of the cover, in order to get a performing product.

3. Automatic sewing system with labelling device:

Electronic high speed overlock 1 needle – 3 yarns for 5 mm. seam or 2 needles – 4 yarns for 7 mm. seam, with trimmer and sensors to start and stop the sewing,

This system is complete of an automatic device to cut and fold the label from the roll, and include into the seam on the requested position, without affecting productivity.

4. Automatic feeding system:

Rolled carded fibre with foam, memory foam, visco latex, polyurethane foam or similar are fed to the system from this belt with electronic devices.

On demand (Optional device) it is supplied a special conveyor for manual feeding; the same operator can place the product and then the cover, without affecting the productivity. See photo on the front page,

5. Automatic conveying system on demand “optionally”:

SYSTEM FOR THE PRODUCTION OF PILLOWS AND FURNISHING CUSHIONS mod.CN400

The unit CN400 is an automatic line for the production of pillows and cushions which important feature is the big productivity.

This system is composed of a stuffing machine complete with automatic feeding belt to convey the produce (rolled carded fibre, memory foam, visco latex and similar), of a system for positioning the pillowcase or cover, of an automatic sewing system with overlock machine (3 or 4 yarns) and of a labelling device (cut of label from the roll to be folded and included into the seam without affecting production time).

The Unit CN400 has a program suitable to different types and sizes of pillows and suitable to different kinds of fibre of different weights and to several products like visco latex, memory foam, polyurethane and similar. It is also suitable to different kinds of pillowcases and covers, in cotton, or nonwoven fabric or stretch fabric.

The production consists of the following phases: the operator inserts the cover and starts the automatic cycle for the feeding and the stuffing of the material, the pillows positioning to the sewing line and the pillow closing with label.

The unit CN400 is able to reduce the labour costs, the space into the production area, the dead time necessary to move the product. At the same time, it is able to guarantee a big output with a satisfactory quality of the finished product, without skilled personnel.

Only one operator is necessary to start the cycle, positioning the cover, being able to get 6 – 7 pillows or cushions / minute, stuffed and closed, ready to be packed.

Production depends on the size and type of products.

Product features:

STANDARD SIZES FOR FURNISHING CUSHIONS:

Length min/max: 42/50 cm.

Width min/max: 42/50 cm.

STANDARD SIZES FOR PILLOWS:

Length min/max: 70/90 cm.

Width min/max: 42/50 cm.

We can arrange for other sizes on demand.

Ask about:

Ask about:

More information

More information Drukuj / Print

Drukuj / Print