It is provided in 2 different versions that differ from each other only in their cutting length. Machine automation is controlled by the electronic programmer included in the control panel. The easy-to-use programmer can contain up to 99 different programs, which in turn are capable of memorizing 14 different cutting settings. Using the programmer it’s possible to set the travel distance of the machine, a useful function should it be necessary to perform work on small blocks. Cutting takes place in a direction of travel recomposing the cut from the opposite direction, its speed can be adjusted using the potentiometer (located on the control console) as a function of material to be cut. Its progressive start and gradual deceleration ensure a very high cutting quality.

Perfect blade sharpening is guaranteed thanks to a pair of motorized grinding wheels located in full view within the front flywheels. The blade guide unit can be inclined via manual hydraulic operation, allowing superb adjustability of the cutting angle.

Automatic stopping when the machining is complete allows the operator to abandon the machine once it has started.

| VOLTAGE | |||

| 380 V, 50 Hz | |||

| POWER CONSUMPTION | |||

| 9 kW | |||

| BLADE ROTATION SPEED | |||

| 1400 rpm | |||

| OPERATOR SPOT LOUDNESS LEVEL | |||

| 3930 kg | |||

| WEIGHT | BPOT 22 | BPOT 44 | |

| BPOT 22/44 | 3930 kg | 5095 kg | |

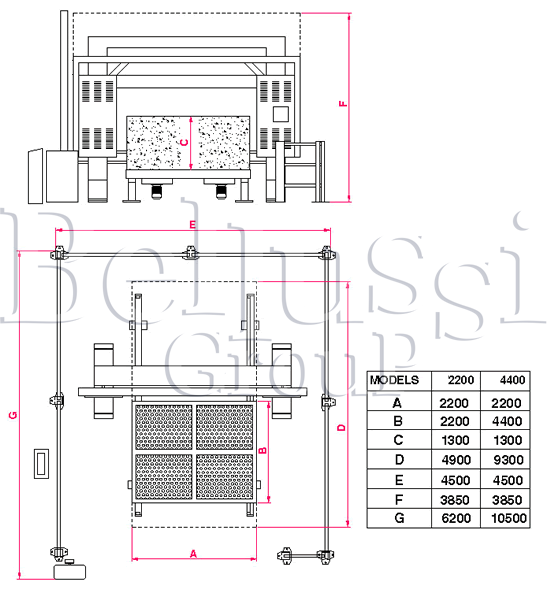

| FOAM CUTTING DIMENSIONS | LENGTH | WIDTH | HEIGHT |

| BPOT 22 | 2200 mm | 2200 mm | 1300 mm |

| LENGTH | WIDTH | HEIGHT | |

| BPOT 44 | 2200 mm | 2200 mm | 1300 mm |

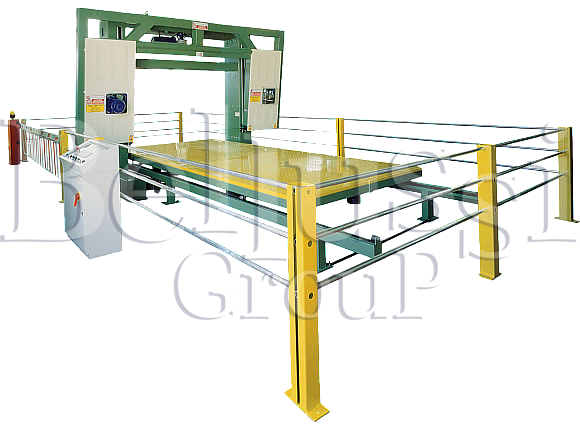

HORIZONTAL CUTTING MACHINE BPOT22-BPOT44

It is provided in 2 different versions that differ from each other only in their cutting length. Machine automation is controlled by the electronic programmer included in the control panel. The easy-to-use programmer can contain up to 99 different programs, which in turn are capable of memorizing 14 different cutting settings. Using the programmer it’s possible to set the travel distance of the machine, a useful function should it be necessary to perform work on small blocks. Cutting takes place in a direction of travel recomposing the cut from the opposite direction, its speed can be adjusted using the potentiometer (located on the control console) as a function of material to be cut. Its progressive start and gradual deceleration ensure a very high cutting quality.

Perfect blade sharpening is guaranteed thanks to a pair of motorized grinding wheels located in full view within the front flywheels. The blade guide unit can be inclined via manual hydraulic operation, allowing superb adjustability of the cutting angle.

Automatic stopping when the machining is complete allows the operator to abandon the machine once it has started.

| VOLTAGE | |||

| 380 V, 50 Hz | |||

| POWER CONSUMPTION | |||

| 9 kW | |||

| BLADE ROTATION SPEED | |||

| 1400 rpm | |||

| OPERATOR SPOT LOUDNESS LEVEL | |||

| 3930 kg | |||

| WEIGHT | BPOT 22 | BPOT 44 | |

| BPOT 22/44 | 3930 kg | 5095 kg | |

| FOAM CUTTING DIMENSIONS | LENGTH | WIDTH | HEIGHT |

| BPOT 22 | 2200 mm | 2200 mm | 1300 mm |

| LENGTH | WIDTH | HEIGHT | |

| BPOT 44 (mm) | 2200 mm | 2200 mm | 1300 mm |

Ask about:

Ask about:

More information

More information Drukuj / Print

Drukuj / Print