There are 3 versions of this machine, which differ only in cutting dimensions. Version 2200-2450 is equipped with a rotary work table to perform the re-cutting of the same profile turned 90 °. The automation of the machine is controlled by personal computer software with a touch system located on the dashboard. To get the desired shape of the cut you can use: digitizer table, scanner or you can load a drawing created in the CAD program. Cutting is done by erosion with a steel wire with a core consisting of a number of wires wrapped around the spiral. The cutting speed is adjusted by means of a potentiometer placed on the dashboard depending on the density of the block and the shape to be cut. The machine is equipped with an effective dust absorber generated during operation.

| NOMINAL POWER |

| 7,7 kW |

| DUST ABSORBER |

| 2,3 kW |

| CUTTING SYSTEM |

| WIRE |

| CUTTING SPEED |

| 1-7 m/min |

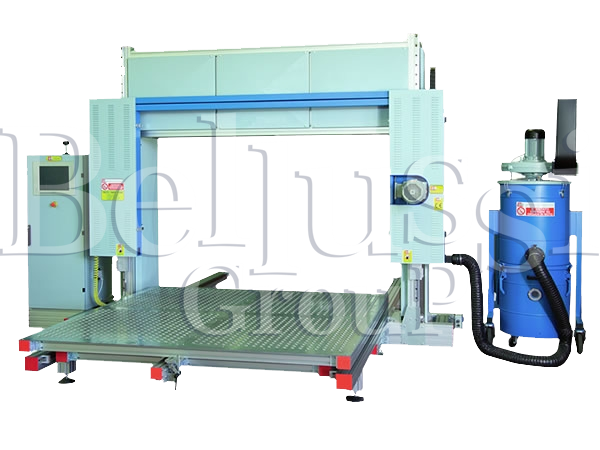

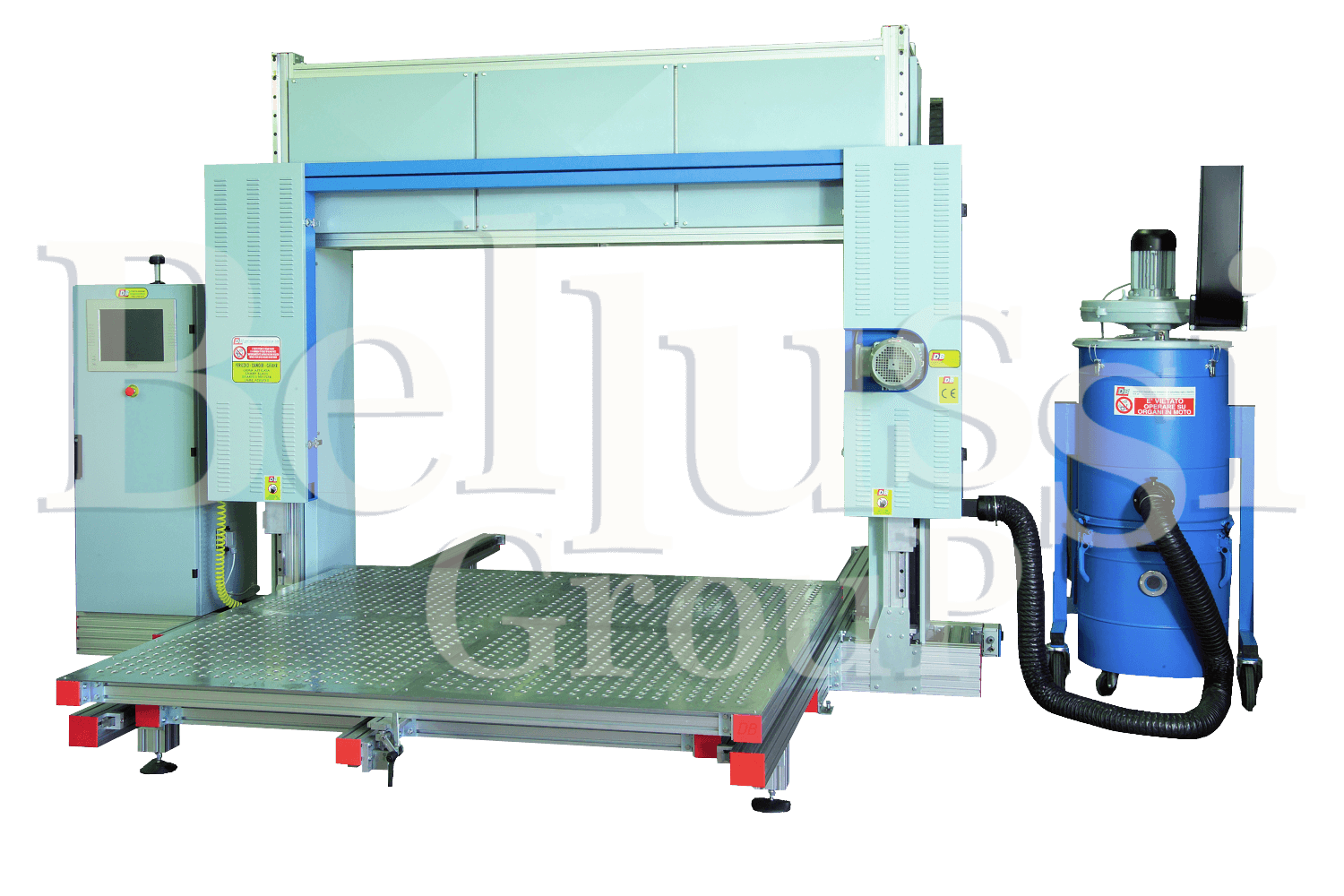

CONTOUR WIRE CUTTING MACHINE BKD-22-24-44

There are 3 versions of this machine, which differ only in cutting dimensions. Version 2200-2450 is equipped with a rotary work table to perform the re-cutting of the same profile turned 90 °. The automation of the machine is controlled by personal computer software with a touch system located on the dashboard. To get the desired shape of the cut you can use: digitizer table, scanner or you can load a drawing created in the CAD program. Cutting is done by erosion with a steel wire with a core consisting of a number of wires wrapped around the spiral. The cutting speed is adjusted by means of a potentiometer placed on the dashboard depending on the density of the block and the shape to be cut. The machine is equipped with an effective dust absorber generated during operation..

| NOMINAL POWER |

| 7,7 kW |

| DUST ABSORBER |

| 2,3 kW |

| CUTTING SYSTEM/strong> |

| WIRE |

| CUTTING SPEED |

| 1-7 m/min |

Ask about:

Ask about:

More information

More information Drukuj / Print

Drukuj / Print