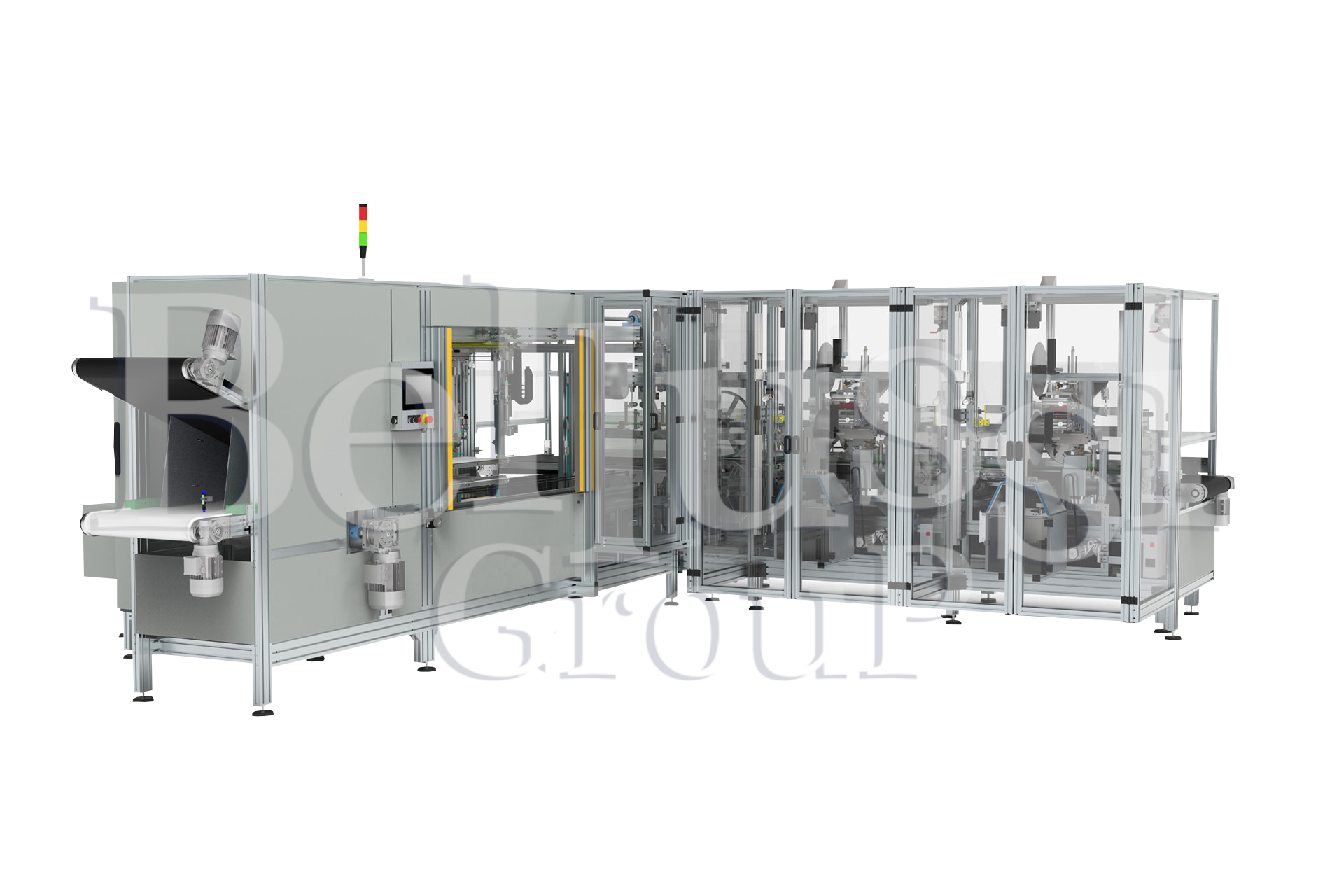

This newest innovative line produces pillows of any sizes, of several kinds of fiber, and different cover material (cotton, polyester, no woven).

Thanks to an advanced software and a simplified operating system, the machine can easily change and in short time the production program.

This technology answers to the needs of customers worldwide reducing the costs in manufacturers’ plants, maximizing efficiency, improving the quality.

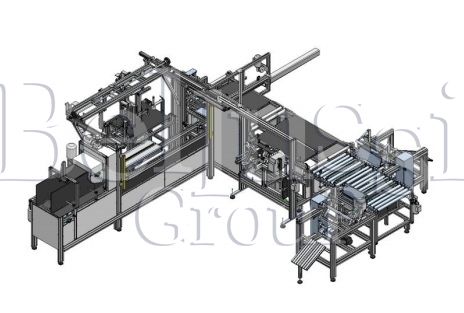

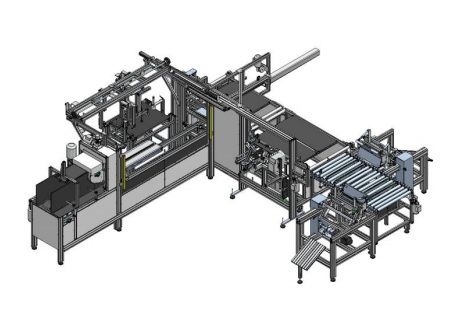

CLEP is an automatic line specific for the manufacturing of pillows and fashion cushions in carded rolled fiber designed for high performances at reduced costs.

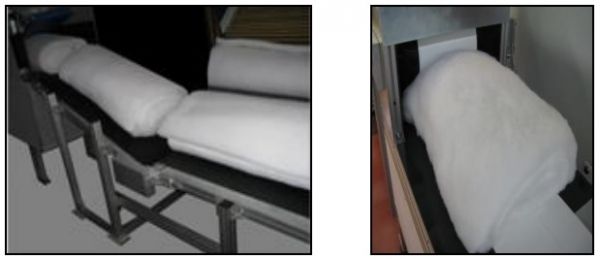

• Electronic stuffing machine equipped with twin belt conveyors, detecting automatically the supply of the fiber and providing the constriction of the material to be transferred into the cover;

• Robotic system for the collection of the cover from the lateral stock box; this innovative unique system takes the place of the operator assuring a perfect alignment and positioning of the cover.

• Robotic system to control the cover tension during the transfer of the pillow to the sewing zone;

• Automatic overlock sewing system, 3 or 4 yarns, to close the open side of the pillow;

• Automatic labelling device preparing the label from the roll and inserting it into the seam, without affecting the production time.

• Robotic system engineered to shake the pillow in order to make it uniform and get the highest quality.

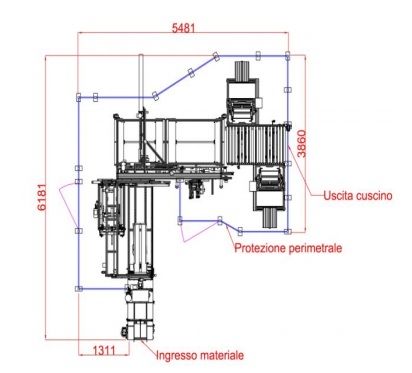

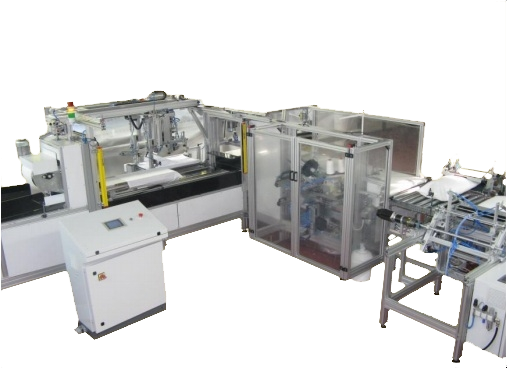

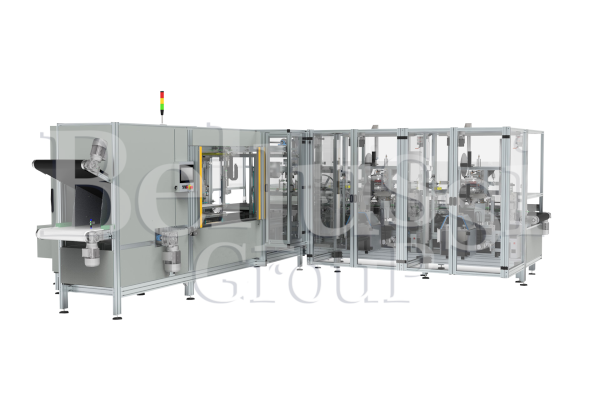

AUTOMATIC LINE FOR PILLOWS AND CUSHIONS CLEP

This newest innovative line produces pillows of any sizes, of several kinds of fiber, and different cover material (cotton, polyester, no woven).

Thanks to an advanced software and a simplified operating system, the machine can easily change and in short time the production program.

This technology answers to the needs of customers worldwide reducing the costs in manufacturers’ plants, maximizing efficiency, improving the quality.

CLEP is an automatic line specific for the manufacturing of pillows and fashion cushions in carded rolled fiber designed for high performances at reduced costs.

This innovative line is composed of:

• Electronic stuffing machine equipped with twin belt conveyors, detecting automatically the supply of the fiber and providing the constriction of the material to be transferred into the cover;

• Robotic system for the collection of the cover from the lateral stock box; this innovative unique system takes the place of the operator assuring a perfect alignment and positioning of the cover.

• Robotic system to control the cover tension during the transfer of the pillow to the sewing zone;

• Automatic overlock sewing system, 3 or 4 yarns, to close the open side of the pillow;

• Automatic labelling device preparing the label from the roll and inserting it into the seam, without affecting the production time.

• Robotic system engineered to shake the pillow in order to make it uniform and get the highest quality.

Product features

FASHION CUSHIONS:

Length : from 42 to 50 cm.

Width: from 42 to 50 cm.

SLEEPING PILLOWS:

Length: from 60 to 90 cm.

Width: from 42 to 50 cm.

Line performances:

Automatic operation: up to 5/6 pillows/minute.

Semiautomatic operation: up to 6/7 pillows/minute.

Ask about:

Ask about:

More information

More information Drukuj / Print

Drukuj / Print