• The SR5 HMI is a pre-weighing and filling machine for multiple-chamber sofa cushions. The machine is specifically built for short polyester fibres, ballfibre, feather, down, shredded foam or any blend of these materials.

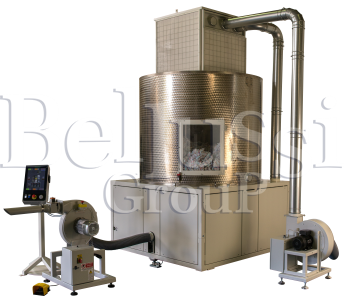

The machine consists of a four-cubic meter storage silo which feeds 3 weighing bins on load cells through motorized shutters. The bins are connected to a blower with variable turbine speed which is activated by a foot pedal. The filling material in the storage silo is kept in motion by a horizontal rotor.

• Topping up of the storage silo, weighing the filling material in the three bins and filling the cushion chambers can all take place simultaneously, hence there is no downtime during operations.

• In case of an accidental overfill an automatic weight-correction system removes the excess material, bringing the bin back to its target weight. This material is directly blown back into the buffer silo, therefore avoiding unnecessary waste or contamination.

• For each SKU an individual data set including the filling sequence, individual cushion chamber-weights, weight tolerance and filling material characteristics can be memorized on the PLC. The storage capacity of the PLC is 800 SKU’s with a maximum of 30 chambers each. More data sets can be stored on an external USB memory and downloaded when required. Once stored, each individual data set can be called up for a production run at any time without having to be re-programmed.

• All processes such as data set-programming and normal machine operations are performed and controlled on a 15” HDI touchscreen. The screen is mounted on a mobile stand, allowing it to be positioned in the most convenient and comfortable position for the machine operator.

• This truly innovative pre-weighing and filling machine makes cushion filling incredibly fast and accurate.

• The machine can be combined with other equipment such as our bale breaker, fibre fine opener, blender and our foam shredder to form a complete production line.

• The machine is built according to the requirements of the European Directives 2006/42/CE, 2004/108/CE, 2006/95/CE and subsequent amendments. The machine duly bears the CE marking.

| MOTOR TYPE | |||

| 3x motor, 3 ph, 6 kW | |||

| AIR PRESSURE | |||

| 6 BAR | |||

| WEIGHT | |||

| 950 kg | |||

| DIMENSIONS (mm) | LENGTH | WIDTH | HEIGHT |

| SR5-HMI (mm) | 3800 | 2100 | 3400 |

AUTOMATIC FILLING SILO SR5-HMI

• The SR5 HMI is a pre-weighing and filling machine for multiple-chamber sofa cushions. The machine is specifically built for short polyester fibres, ballfibre, feather, down, shredded foam or any blend of these materials.

The machine consists of a four-cubic meter storage silo which feeds 3 weighing bins on load cells through motorized shutters. The bins are connected to a blower with variable turbine speed which is activated by a foot pedal. The filling material in the storage silo is kept in motion by a horizontal rotor.

• Topping up of the storage silo, weighing the filling material in the three bins and filling the cushion chambers can all take place simultaneously, hence there is no downtime during operations.

• In case of an accidental overfill an automatic weight-correction system removes the excess material, bringing the bin back to its target weight. This material is directly blown back into the buffer silo, therefore avoiding unnecessary waste or contamination.

• For each SKU an individual data set including the filling sequence, individual cushion chamber-weights, weight tolerance and filling material characteristics can be memorized on the PLC. The storage capacity of the PLC is 800 SKU’s with a maximum of 30 chambers each. More data sets can be stored on an external USB memory and downloaded when required. Once stored, each individual data set can be called up for a production run at any time without having to be re-programmed.

• All processes such as data set-programming and normal machine operations are performed and controlled on a 15” HDI touchscreen. The screen is mounted on a mobile stand, allowing it to be positioned in the most convenient and comfortable position for the machine operator.

• This truly innovative pre-weighing and filling machine makes cushion filling incredibly fast and accurate.

• The machine can be combined with other equipment such as our bale breaker, fibre fine opener, blender and our foam shredder to form a complete production line.

• The machine is built according to the requirements of the European Directives 2006/42/CE, 2004/108/CE, 2006/95/CE and subsequent amendments. The machine duly bears the CE marking.

| MOTOR TYPE | |||

| 3x motor, 3 ph, 6 kW | |||

| AIR PRESSURE | |||

| 6 BAR | |||

| WEIGHT | |||

| 950 kg | |||

| DIMENSIONS (mm) | LENGTH | WIDTH | HEIGHT |

| SR5-HMI (mm) | 3800 | 2100 | 3400 |

Zadaj pytanie na temat:

Zadaj pytanie na temat:

More informations

More informations Drukuj / Print

Drukuj / Print